Harnessing the power of Siemens motion control programmable logic controllers (PLCs) can revolutionize your automation processes, offering unrivaled precision and reliability. However, to fully leverage these sophisticated devices, it’s crucial that you understand their proper usage and potential. With this comprehensive guide, you can learn how to effectively use a Siemens motion control PLC in your operations to gain an edge in today’s competitive industrial landscape. Here’s everything you need to know about the equipment and the brand.

The Legacy of the Siemens PLC Brand

Before we delve deeper into the equipment itself, we want to first give you a bit of an overview of the company. Siemens is a brand synonymous with innovation and reliability; as such, it has been one of the top players in the automation industry for decades. The inception of the Siemens PLC kick-started a new era in industrial control systems, revolutionizing processes across various sectors.

In the mid-twentieth century, Siemens recognized the need for an efficient, flexible solution to manage complex industrial processes. Responding to this need, the company developed its first PLC, a groundbreaking device that combined the flexibility of computer programming with the robustness of industrial hardware. This innovative blend marked a significant departure from traditional relay-based systems, providing unprecedented control over complex operations and positioning Siemens as a pioneer in the field.

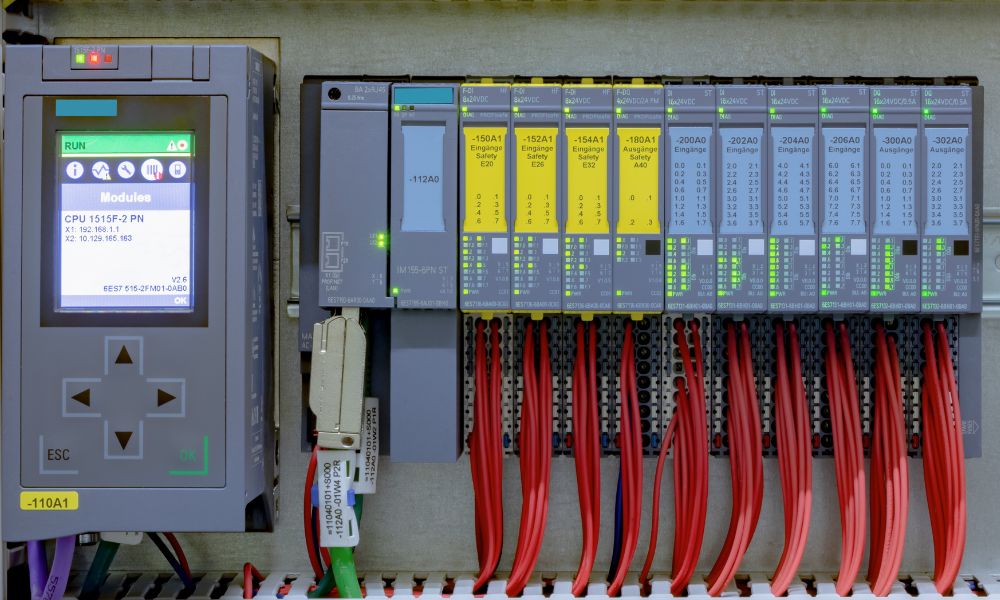

Over the years, Siemens has consistently pushed the boundaries of PLC technology. With each new product line, the brand demonstrates its commitment to delivering high-quality, reliable, and technologically advanced solutions. From the S5 series, revered for its robustness and reliability, to the current generation S7 series, renowned for its speed and functionality, Siemens has set the standard for PLC performance.

Today, Siemens PLCs are trusted products worldwide, their reputation bolstered by the brand’s unwavering commitment to excellence. From automotive manufacturing to water treatment plants, Siemens PLCs are indispensable tools, driving efficiency and precision in countless applications.

Installing and Setting Up Your Siemens PLC

Proper installation and setup are the first steps toward leveraging the full potential of your Siemens PLC. This process requires careful consideration of several factors, including location selection, operation conditions, device accessibility, and the installation itself.

Selecting the Right Location

Choosing an optimal location for your Siemens PLC is crucial. The location should be free of excessive dust, moisture, and extreme temperature fluctuations. It should also allow for adequate ventilation to prevent overheating. A well-chosen location not only ensures the longevity of your PLC but also enhances its performance.

Considering Operation Conditions

Siemens PLCs are specially designed to perform under diverse operational conditions. However, specific environments may require additional considerations. For instance, locations with high electrical noise or vibration might necessitate special shielding or mounting solutions. By thoroughly considering operational conditions, you can ensure that your PLC operates efficiently and reliably.

Noting Device Accessibility

Accessibility is another key factor in PLC installation. Always install your PLC in a location that allows easy access for inspection, maintenance, and potential troubleshooting. This strategic placement can significantly reduce downtime, helping maintain a high level of productivity in your operations.

Installing Your New PLC

Once you’ve addressed these considerations, you can install your new Siemens PLC. Follow the detailed installation guide provided by Siemens, ensuring you carry out each step meticulously. From mounting to wiring, every stage is crucial for the effective functioning of your PLC. The installation process, when done correctly, sets the foundation for successful PLC performance, enabling you to fully leverage the power and efficiency of Siemens automation technology.

Programming Your Siemens PLC

Once you have your new device installed, the next phase of properly using a Siemens motion control PLC is programming it to do what you need. Programming your Siemens PLC is a critical aspect that dictates the efficiency and the overall output quality of your operations. The following factors are crucial things to keep in mind.

Compatible Programming Languages

Siemens PLCs demonstrate their versatility by supporting a range of programming languages. Among these languages are Ladder Logic (LAD), Structured Text (STL), and Function Block Diagram (FBD). Each language presents unique advantages, allowing you to choose the one that best suits your applications. This compatibility with multiple languages enables you to tailor your PLC’s performance to your specific needs, ensuring optimal control over your industrial processes.

Siemens Advanced Software Solutions

Siemens PLCs come with a wide range of advanced software solutions. The TIA Portal, a notable example, offers an integrated engineering framework that simplifies the programming process. Its intuitive interface and simulation capabilities facilitate the creation, testing, and refinement of your PLC programs. By leveraging these advanced software solutions, you can maximize the efficiency and precision of your PLC operations.

Siemens PLC Optimization

Optimizing your Siemens PLC goes beyond programming—it also involves a comprehensive understanding of your operational needs and aligning them with the capabilities of your PLC. You can fine-tune factors such as cycle time, memory usage, and network communication to enhance your PLC’s performance. By implementing a strategic approach to optimization, you can ensure your Siemens PLC delivers consistent, high-quality results, contributing significantly to your operational success.

Troubleshooting Common Issues With Siemens PLCs

Despite their robust design and advanced technology, Siemens PLCs may occasionally encounter issues. Common problems include communication errors, incorrect programming, and hardware malfunctions. When troubleshooting, it’s crucial to systematically diagnose the problem, starting with the most common causes. Siemens provides comprehensive documentation and support to assist with this process, ensuring your PLC quickly returns to optimal functionality.

Ensuring Safety While Using Siemens PLCs

Additionally, safety is paramount when working with Siemens PLCs. Users should adhere to Siemens’ safety guidelines, which cover aspects such as electrical safety, handling, and maintenance. Regular inspections and preventive maintenance can help you detect potential safety risks early and mitigate them effectively. By prioritizing safety, you not only protect your personnel and equipment but also ensure the long-term reliability and efficiency of your system.

Correctly using Siemens products means taking the time to accurately install, program, and monitor them as you use them in your business. At PLC Direct, we’re committed to providing top-quality PLCs, including Siemens PLCs, to help you optimize your industrial automation processes. The products we offer are reliable and designed to withstand the rigors of industrial environments. Let PLC Direct guide you on the journey as you transform your industrial automation processes to enhance efficiency, increase reliability, and drive productivity.