Programmable logic controllers (PLCs) are a vital part of bringing your operations into the 21st century. However, if you’re going to make the most of their implementation, you need to know how they work. Here’s what you need to know about the different components of a PLC and what each part does.

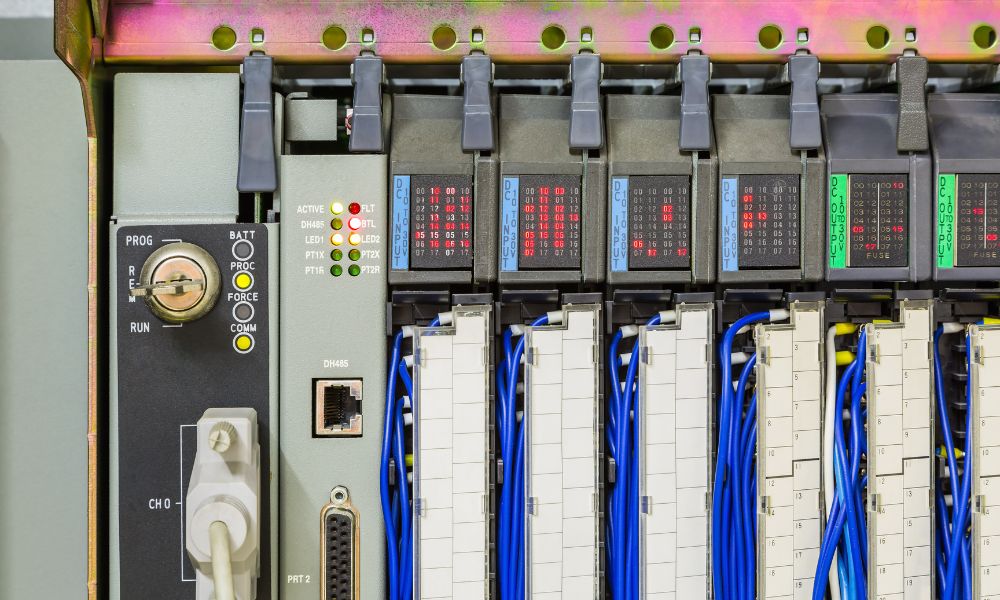

Central Processing Unit (CPU)

A central processing unit is the brain of the PLC, managing all the input and output signals. It takes instructions from the user program and translates them into actions that the other components can execute in real time. The CPU also stores the user program and performs diagnostics to ensure the PLC is operating correctly. The performance and speed of the CPU are critical factors in the overall performance of a PLC.

Input/Output (I/O) System

The I/O system connects sensors, switches, and other input devices to the PLC. The inputs can come from a variety of sources, such as temperature sensors, proximity switches, and pressure transducers. The I/O system converts the physical signals into digital signals that the CPU can recognize. Similarly, the I/O system sends output signals to other devices, such as motors and valves.

Memory

A PLC uses different types of memory to store different types of information. The CPU uses read-only memory (ROM) to store the user program, which contains the instructions for the PLC’s operation. Random-access memory (RAM) stores data temporarily during the program’s execution, allowing the CPU to access critical data quickly. Electrically Erasable Programmable Read-Only Memory (EEPROM) aids in managing information that you, as the user, can change or erase as needed. This includes setpoints and configuration data.

Power Supply

A PLC system requires stable and reliable power to operate correctly. The power supply converts the incoming AC or DC power to the appropriate voltage level needed by the different components. Most PLC systems have built-in redundancies, where a secondary power supply can take over if the primary one fails.

Programming Environment

Another important PLC component to know about and understand how it works is the programming environment. This is where users create and edit the PLC program. Program writing occurs in a specialized language called ladder logic, which uses symbols and diagrams to represent logical instructions. Modern PLCs come with user-friendly software that allows users to program the system easily.

These essential components of a PLC work together to provide accurate and reliable control of industrial processes. Understanding how each component works can help you make informed decisions about PLC implementation and identify areas of improvement in your manufacturing operations. At PLC Direct, we carry hundreds of models for you to choose from, including our popular collection of Siemens PLCs, B&R, Omron, and more. Regardless of your desired specifications, we’re confident we have something that will work for you.