Manufacturing and industrial automation have been evolving at a rapid pace ever since the advent of programmable logic controllers (PLCs). These amazing devices transform the way businesses approach their production processes, from their humble creation to modern, advanced systems. We will take you on a journey through the history and evolution of programmable logic controllers, highlighting the major milestones, advancements, and their transition into industrial automation.

The First Programmable Logic Controllers

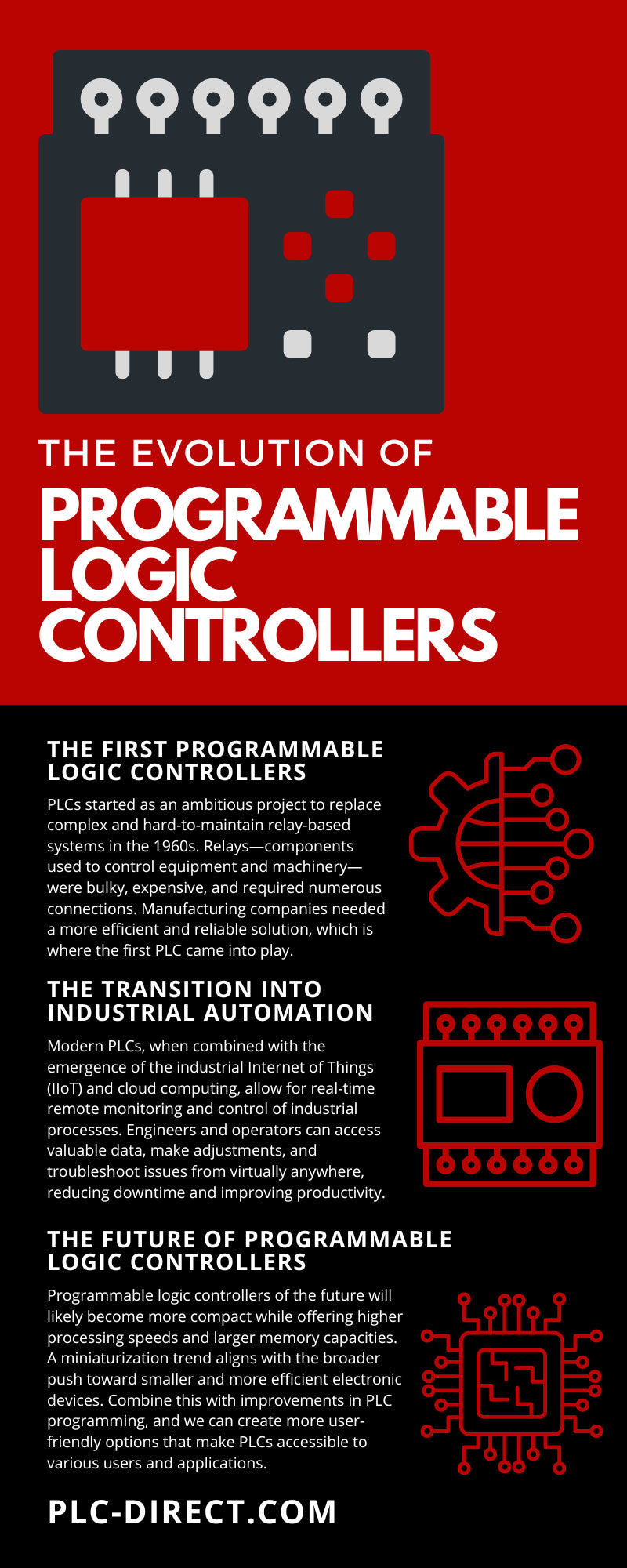

PLCs started as an ambitious project to replace complex and hard-to-maintain relay-based systems in the 1960s. Relays—components used to control equipment and machinery—were bulky, expensive, and required numerous connections. Manufacturing companies needed a more efficient and reliable solution, which is where the first PLC came into play.

The Modular Digital Controller (MODICON) was developed by Richard Morley and Michael Greenberg in 1968. This innovative solution reduced the cost and complexity of manufacturing processes. It used a ladder diagram programming language that was familiar and easy to understand for the technicians who routinely worked with relay diagrams.

This ground-breaking system could be easily re-programmed and adapted to different production processes without steep expenses, making businesses more versatile. The first PLCs were common in the automotive industry for producing cars.

Advancements Over the Years

As technology continued to improve, PLCs could handle a wide variety of applications. Here are some key developments that played a significant role in shaping modern programmable logic controllers:

Microprocessors and Memory Enhancements

The introduction of microprocessors and the improvement of semiconductor technology led to faster processing speeds and increased memory capacity. This allowed PLCs to handle larger and more complex programs while becoming smaller and more energy efficient.

Communication Capabilities

The advent of communication protocols like RS-232, RS-485 and later, Ethernet, allowed for better connectivity between these devices and other components in a manufacturing plant. This enabled facilities to share information and data easily, significantly improving productivity.

Graphical Programming

As PLC programming software evolved, graphical programming languages like sequential function charts (SFC) and function block diagrams (FBD) emerged as alternatives to ladder logic. These options simplified the programming process and made it easier for engineers to visualize how various elements of the control system worked together.

Human-Machine Interface (HMI) Integration

The development of user-friendly touchscreens and human-machine interface technology allowed for seamless interaction between manufacturing operators and PLCs. This improved troubleshooting and maintenance processes and allowed operators to monitor and control the plant floor in real time.

The Transition Into Industrial Automation

While the automotive industry was the first to enjoy the perks of PLCs in manufacturing operations, it certainly wasn’t the last. In fact, the evolution of programmable logic controllers played a pivotal role in bringing about industrial automation. With the advent of modern PLCs, businesses could optimize their processes, minimize human intervention, and boost production. We will explain how PLCs have contributed to the rise of industrial automation:

Flexibility and Scalability

Today's PLCs can adapt to a wide range of applications, making them suitable for businesses of all sizes. The modular design of programmable logic controllers allows companies to customize and scale their control systems according to their needs.

Remote Monitoring and Control

Modern PLCs, when combined with the emergence of the industrial Internet of Things (IIoT) and cloud computing, allow for real-time remote monitoring and control of industrial processes. Engineers and operators can access valuable data, make adjustments, and troubleshoot issues from virtually anywhere, reducing downtime and improving productivity.

Integration With Advanced Technologies

PLCs now work seamlessly with advanced technologies such as artificial intelligence (AI), machine learning, and robotics. This integration creates new possibilities for advanced analytics and autonomous operation in manufacturing.

Safety and Reliability

With built-in safety features and high reliability, modern PLCs can ensure the safe and smooth operation of complex industrial processes. They can withstand harsh industrial environments while functioning, even in the event of a power outage or network failure.

The Future of Programmable Logic Controllers

The future of PLCs looks promising, with technological advancements expected to drive improvements in communications, hardware, and software. As more industries continue to embrace automation, programmable logic controllers will undoubtedly play a pivotal role in shaping this landscape.

One major trend we expect to see is the incorporation of PLCs with emerging technologies like AI and the Internet of Things (IoT). As stated previously, we’ve already seen the beginnings of this, but these technologies could enable PLCs to handle more complex tasks, make predictive decisions, and eventually operate autonomously. For instance, AI may aid in enhancing preventative maintenance, reducing machine downtime in a facility.

Programmable logic controllers of the future will likely become more compact while offering higher processing speeds and larger memory capacities. A miniaturization trend aligns with the broader push toward smaller and more efficient electronic devices. Combine this with improvements in PLC programming, and we can create more user-friendly options that make PLCs accessible to various users and applications.

We anticipate to find new uses for PLCs beyond manufacturing and industrial settings. They could play a crucial role in smart city applications, renewable energy systems, and advanced transportation solutions. With their ability to connect to a wide range of communication modules, the possibilities for future use are only limited by our imagination!

Looking back at the evolution of PLCs, it's clear that these devices revolutionized the world of manufacturing and industrial automation. From their humble beginnings in the 1960s to the powerful, versatile systems we see today, programmable logic controllers have adapted to meet the changing needs of countless industries. As we move into the future, we can expect PLCs to continue evolving, enhancing productivity and innovation in the manufacturing sector. Regardless of your industry, PLCs will remain a key component in your journey toward operational efficiency.

If you are interested in incorporating one of these advanced devices into your own systems, PLC Direct can help you. As a trusted PLC distributor, we carry a large selection of models from the industry’s top manufacturing brands. Rest assured that you will get equipment that completely changes your operations for the better!