The use of programmable logic controllers (PLCs) has become increasingly important in modern manufacturing. PLCs offer businesses the ability to create automated systems, which can perform specific tasks based on their programming. PLCs are versatile, durable, reliable, and customizable, meaning you can use them for multiple applications. However, purchasing the ideal PLC for your business can be challenging if you don’t have the technical understanding of the different models available. We will provide some insight into choosing the right PLC for your application and discuss a few things you should keep in mind.

Identify Your Application’s Needs

The first step in selecting the perfect PLC is to identify how you want to apply the device and what the task will entail. Consider the number of inputs and outputs needed for your application, as well as the types of inputs and outputs required. Identify the speed at which the system needs to operate, and the accuracy needed for the application. Having a clear understanding of these requirements will aid you in your search by helping you shorten your list of potential options.

Choose the Right Platform

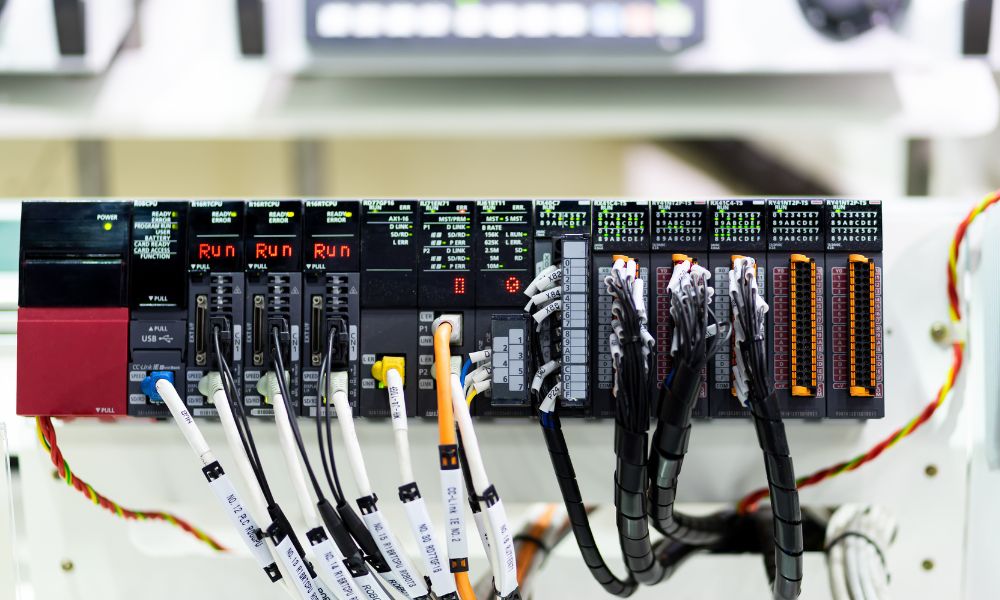

PLCs come in varying sizes, and each model can cater to a certain task or operational scale. There are small, medium, and large devices available on the current PLC market. In general, small PLCs are great for simple applications, medium-sized PLCs for moderate applications, and large PLCs for complex applications. Therefore, it’s important to choose the right platform depending on the scale of your application.

Select the Right I/O

PLCs have different input and output options, depending on the model and brand you select. Ensure that the PLC you choose has the right input/output options for your application. For example, if your application requires analog inputs or outputs, ensure that the PLC has analog input/output capabilities. You should also always consider the number of input/output points needed for the application.

Look for User-Friendly Software

Another effective tip for choosing the right PLC for your application is to prioritize devices that use easy-to-understand programming software. PLCs require a computer program to control the system. Therefore, it’s vital that you select a PLC with user-friendly software. This makes it easier and more efficient for the user to program and monitor device operations. The software should have user-friendly menus for navigating and creating programs; it should also be easy to install.

Consider Customization Options

Lastly, consider the customization options available for the PLC. Does the PLC have software that you can modify to include custom functions or features? Will the PLC work with different types of I/O? These are important factors as they offer the flexibility to customize the PLC to your application requirements.

Selecting a PLC that’s right for your company is essential for the efficient operation of your automated system. That’s why our PLC Direct team is here to help you with all your facility automation needs. We’re a premium PLC supplier that acquires a wide range of devices for you to pick from, and we’ll work with you to find the perfect match for your operations.